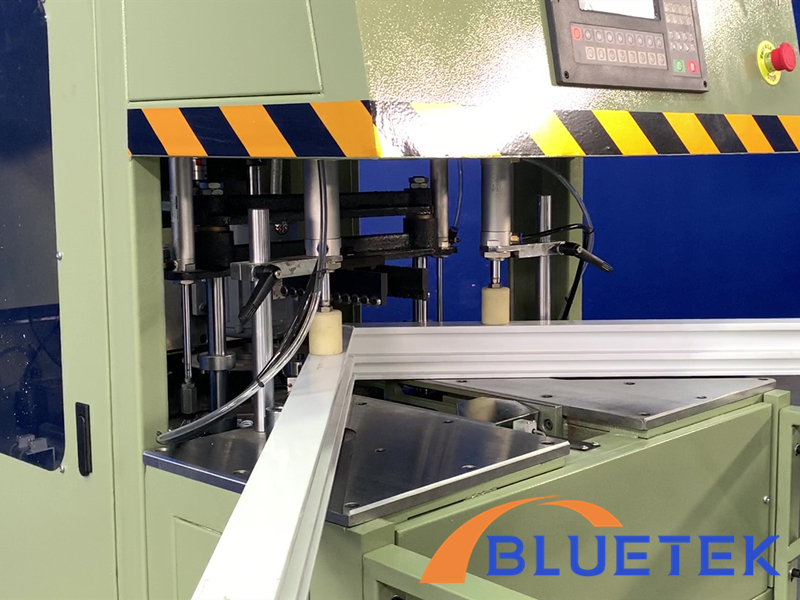

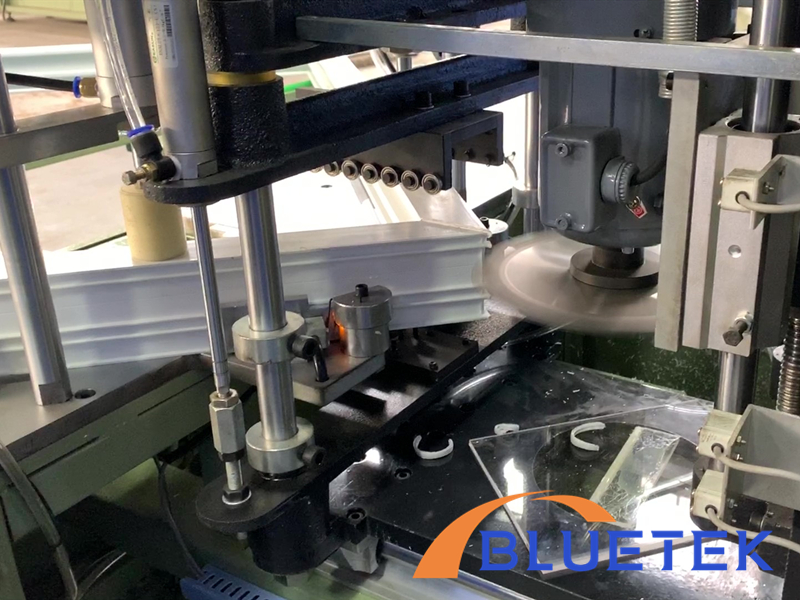

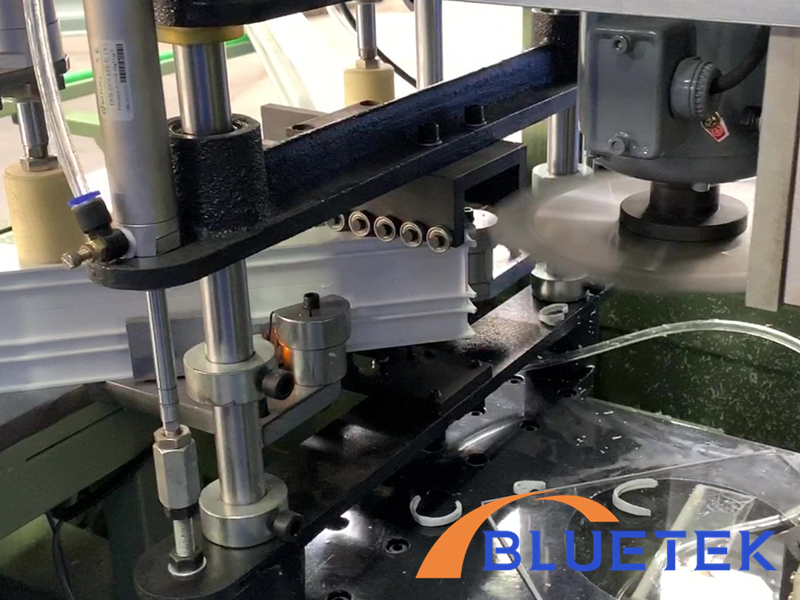

1. The UPVC CNC corner cleaning machine is a special machine used to clean corner welding slag of PVC doors and windows. Knife can cut off the welding slags on the upper and lower surfaces, and the saw blade can clean the outer corners.

2. CNC system control, programming for each window type, you only need to select the corresponding program on the screen to clear the corners, and the efficiency is very high.

3. Graphical user interface, the tool running track can be displayed intuitively;

4. PVC window cnc corner cleaning machine is equipped with a USB interface, the processing program of various specifications can be stored through the external storage tool, and the system can be upgraded regularly through the external storage tool, etc.;

5. Teaching programming function, programming is simple and intuitive, through CNC programming, two-dimensional processing programs can be set.

Technical Parameters

| Product Model | SQJ04-CNC-120 |

| Prodcut Name |

3 Tools UPVC Window CNC Corner Cleaning Machine |

| Air Pressure | 0.6 ~0.8 Mpa |

| Air Consumption | 100L /min |

| Input Power | 5 KW |

| Power Supply | Customize |

| Saw Blade Diameter | φ230mm, 40T |

| Processing Height | 25 ~ 120 mm |

| Processing Width |

25 ~ 120 mm |

| Roatry Speed of Motor | 2840 r/min |

| Weight | 400 KG |

| Overall Dimension | 850*1500*1750 mm |

Detail Pictures

English

English Spanish

Spanish JINAN BLUETEK INTELLIGENT CO.,LTD.

JINAN BLUETEK INTELLIGENT CO.,LTD.