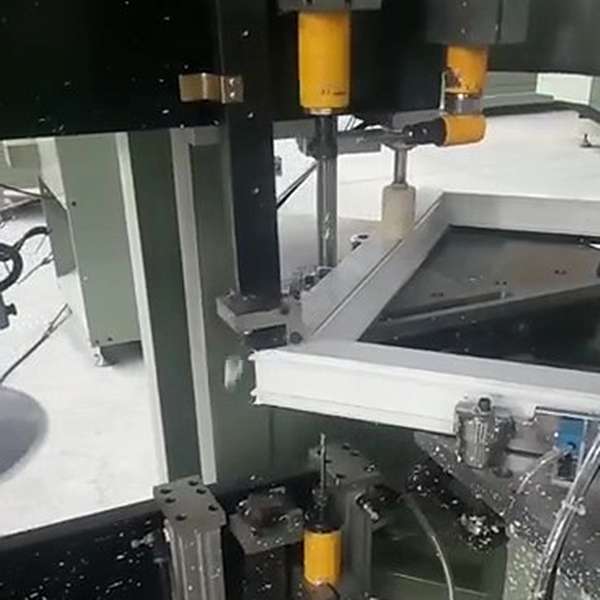

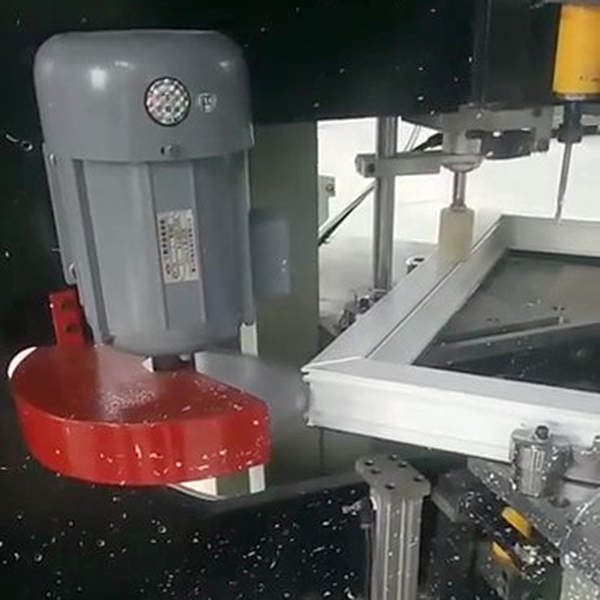

1. The UPVC window CNC corner cleaning machine is used to clean the welding slag of PVC door window 90 degree corner . It adopts a three-axis 6 tools structure, which can effectively clean the outer corner, the upper and lower sides of the profile corner, the inner corner rubber groove and the inner corner seam of the sliding frame slide rail.

2. Saw blade is used to clean the outer corner, knife is used to clean the corner surface ( top and bottom ), and milling cutters are used to clean the inner corner; adopts high-speed frequency conversion motor, the milling speed is fast, and the milling surface is smooth.

3. This UPVC windows corner cleaning machine uses a graphical user interface, all tools path can be displayed intuitively on the screen.

4. Equipped with a USB interface, the processing program of various specifications can be stored through the external storage tool, and the system can be upgraded regularly through the external storage tool, etc.

5. UPVC window automatic corner cleaning machine 6 tools can realize the compensation of arc difference and oblique line difference, which can meet the needs of making high-quality doors and windows with various cross-section profiles.

Technical Parameters

|

Product Model |

SQJ06-CNC-120 |

|

Prodcut Name |

UPVC Window CNC Corner Cleaning Machine 6 Tools |

|

Air Pressure |

0.6 ~0.8 Mpa |

|

Air Consumption |

100L /min |

|

Input Power |

5 KW |

|

Power Supply |

Customize |

|

Saw Blade Diameter |

φ230mm, 40T |

|

Processing Height |

25 ~ 120 mm |

|

Processing Width |

25 ~ 120 mm |

|

Weight |

500 KG |

|

Overall Dimension |

1200*1500*2000 mm |

Detail Pictures

English

English Spanish

Spanish JINAN BLUETEK INTELLIGENT CO.,LTD.

JINAN BLUETEK INTELLIGENT CO.,LTD.