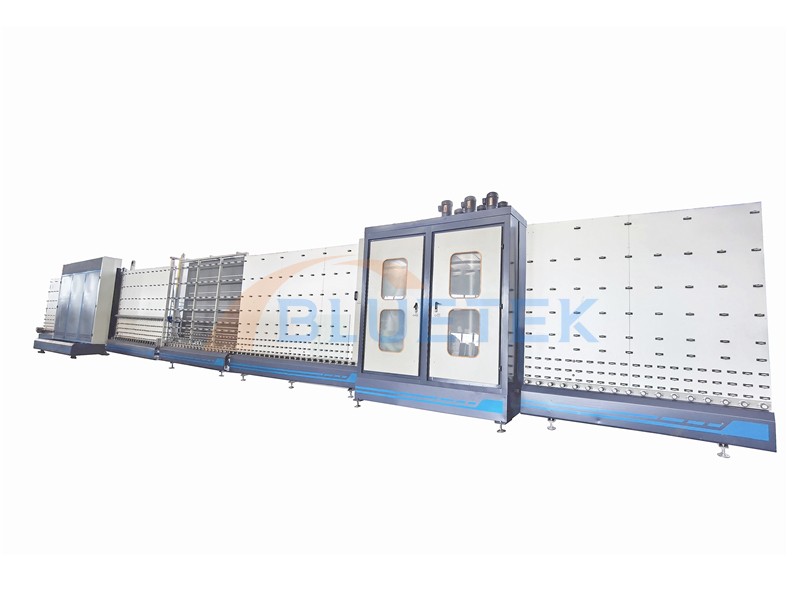

• Vertical full automatic Insulating Glass Making Machine is a machine specially used for producing aluminum spacer insulating glass / double glazing. Double and triple insulating glass, rectangular and special-shaped insulating glass can be produced.

• High productivity. It can complete all functions such as glass conveying, glass cleaning, glass drying, aluminum frame bonding (manual), glass lamination, argon gas filling (optional), and flat pressing. A single shift of eight hours can complete 700 to 800 units of insulating glass.

• Automatically identify coated glass and LOW-E glass; the screen can dynamically display the operation of each section of the machine.

• The washing section of insulating glass making macine is all made of high-quality stainless steel, the imported nylon brush will not scratch the glass surface, and the gap can be automatically adjusted according to the thickness of the glass. Double air knife design, strong and uniform wind, fast drying speed and adjustable temperature.

• The flat pressing of insulating glass adopts servo drive and linear guide rail, which has the highest degree of synchronization, and the flatness of insulating glass is very high.

• Insulating Glass Production Line 's control system and low-voltage electrical appliances all adopt the German Siemens brand, and the pneumatic components and guide rails adopt the Taiwan brand. The machine runs stably and the quality is reliable.

• Maximum processing glass size is 2500mm * 3000mm ( Height * Length ), which can be customized according to customer requirements.

Technical Parameters

| Product Model | LZK2500A |

| Product Name |

Insulating Glass Production Line |

| Total Power | 28 KW |

| Air Pressure | 1 MPa |

| Max. Size of Insulating Glass | 2500*3500mm ( Height * Length ) |

|

Min. Size of Insulating Glass |

400*300mm ( Height * Length ) |

|

Thickness of Original Glass |

3 ~15 mm |

|

Thickness of Insulating Glass |

12 ~50 mm |

|

Washing Speed |

2 ~ 12M / min |

|

Working Speed |

2 ~ 45M / min |

|

Overall Dimension |

23000*1800*3400 mm |

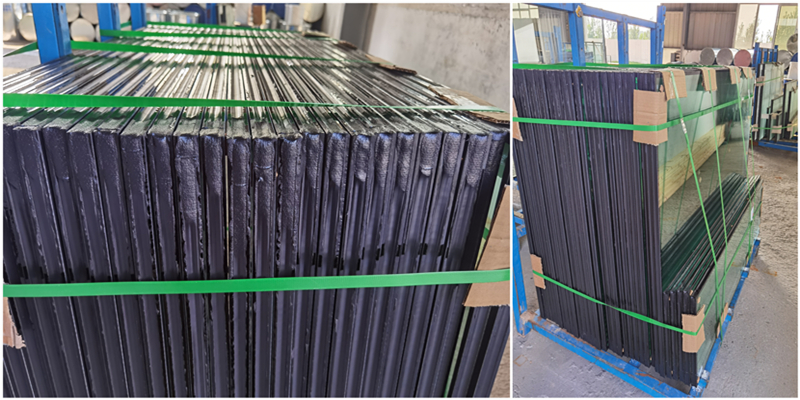

Detail Pictures

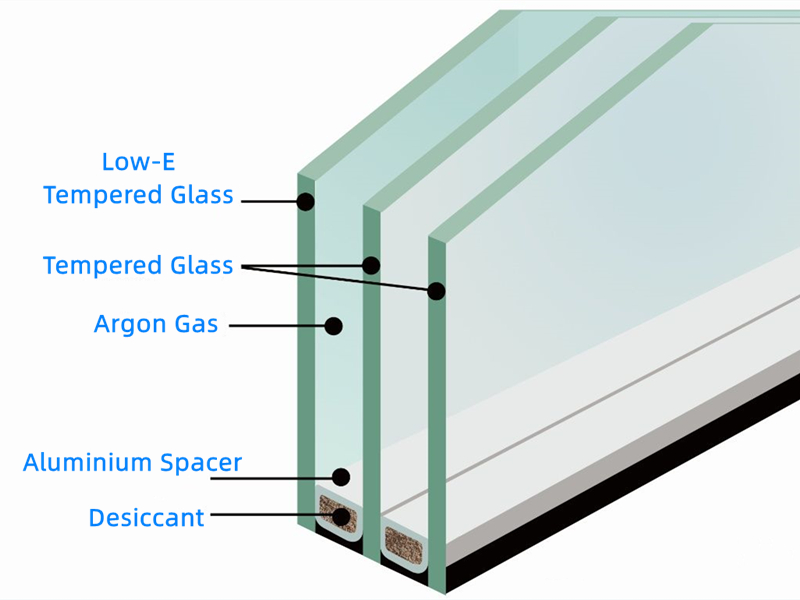

Manufacturing Processes For Insulating Glass ( Aluminium Spacer Bar )

If you want to understand the processing technology of insulating glass, you must know which insulating glass making macine is needed!

The first step is to cut the original glass sheet and cut the glass into the required size and shape (glass cutting machine)

The second step, glass edging, is to ensure the safety of workers during glass processing; if it is LOW-E glass, Low-e film needs to be removed (glass edging machine, film removal machine)

The third step is to bend the aluminum spacer bar into an frame (aluminum spacer bending machine); you can also cut the aluminum bar into 4 pieces, and then connect them into an aluminum frame with gusseted corners, so that no bending machine is needed, and the cost reduce.

The fourth step is to fill the aluminum spacer with 3A desiccant, which can effectively absorb the moisture and impurities in the hollow glass cavity and keep it dry (desiccant filling machine); it also can be manually filled with manual tools to reduce costs.

The fifth step is to apply butyl glue on two sides of the aluminum spacer, which is the first sealing of the insulating glass, which plays a vital role in the sealing and heat insulation of the insulating glass (butyl glue coating machine)

The sixth step, the vertical insulating glass production line can realize glass washing, drying, sticking aluminum spacers, insulating glass installation, and pressing. It only needs to manually stick the aluminum spacer on glass, and other functions are completed automatically. (Vertical insulating glass production line)

The seventh step, the second sealing, coating two-component sealant to the hollow grooves of the aluminum spacer and the glass edge to improve the sealing performance and strength of the insulating glass. (two-component sealant extruder)

The eighth step, fill with argon gas (Gas inflator); also don't need to fill argon gas in insulating glass, according to customer requirements.

English

English Spanish

Spanish JINAN BLUETEK INTELLIGENT CO.,LTD.

JINAN BLUETEK INTELLIGENT CO.,LTD.