• The double glazing machine is a professional machine for processing and producing double-layer and triple-layer insulating glass. It fills the aluminum spacer with 3A desiccant to keep the double glazing dry and clean.

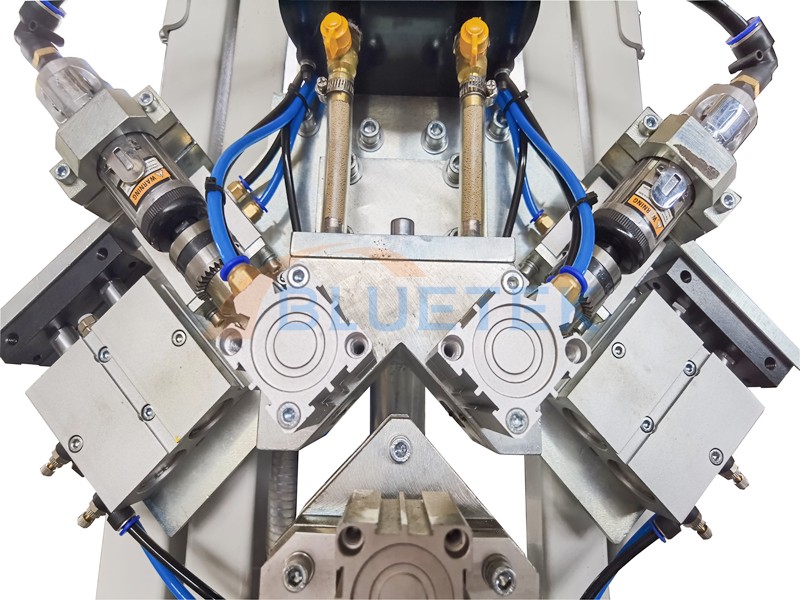

• Function: Drilling holes on two sides of the aluminum spacer at the same time, filling an appropriate amount of 3A desiccant (the filling amount is controlled by time), and then the glue nozzle automatically seals the holes. The height of the drill bits can be adjusted to accommodate different sizes of aluminum spacers.

• Operation Steps: turn on the power supply and air source, turn on the switch of the double glazing machine; turn on the heating switch, so that the temperature of the glue tank rises to 120 degrees Celsius; put the bent aluminum spacer on the clamp, step on the foot switch, Drilling, filling and sealing are will be done automatically.

• The function of filling desiccant in double glazing: adsorb the residual water molecules and organic volatiles in the double glazing interlayer, effectively prevent the glass interlayer from condensation and frost, so that the double glazing remains smooth and transparent at low temperature. At the same time, the problem of twisting and breaking of the double glazing caused by the pressure difference between the inside and outside is fully reduced, and the service life of the double glazing is prolonged.

• Features of double glazing machine : Adopt PLC control system and touch screen operation. Temperature adjustment and time parameters are all set through the touch screen, drilling, filling and sealing are done automatically. Simple operation and high degree of automation. This double glazing machine can greatly improve the production efficiency and quality of insulating glass.

Technical Parameters

Model

FGZ-CNC

Product Name

Double Glazing Machine , Desiccant Filling Machine

Input Power

1.0 KW

Air Pressure

0.6 ~0.8 Mpa

Power Voltage

220V 50Hz

Aluminium Spacer

9 ~ 20 mm

Filling Speed

5 ~ 10 s

Desiccant Diameter

0.5 ~ 0.8 mm

Overall Dimension

1000*1100*2400 mm

Weight

200 KG

Detail Pictures

English

English Spanish

Spanish JINAN BLUETEK INTELLIGENT CO.,LTD.

JINAN BLUETEK INTELLIGENT CO.,LTD.