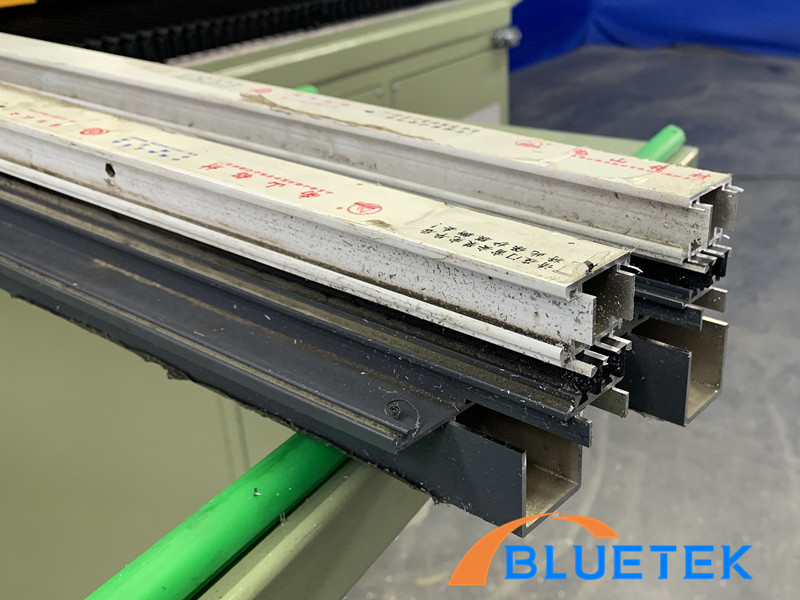

1. The automatic aluminium window end milling machine is mainly used for milling the end face tenon of aluminum alloy door and window mullions, especially the processing of strengthening mullion.

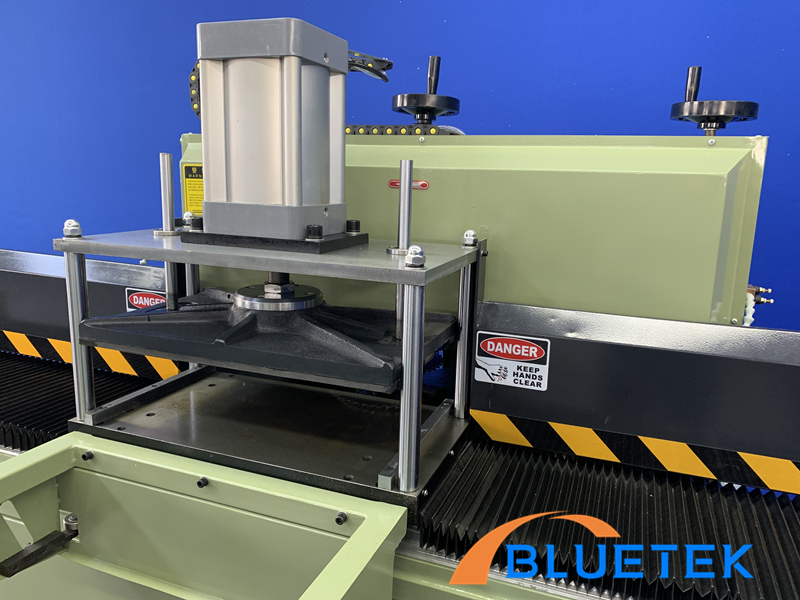

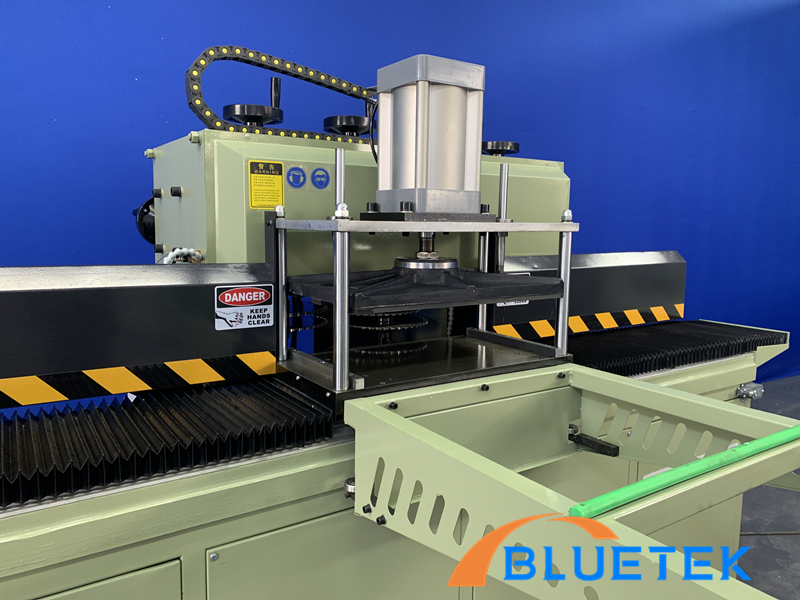

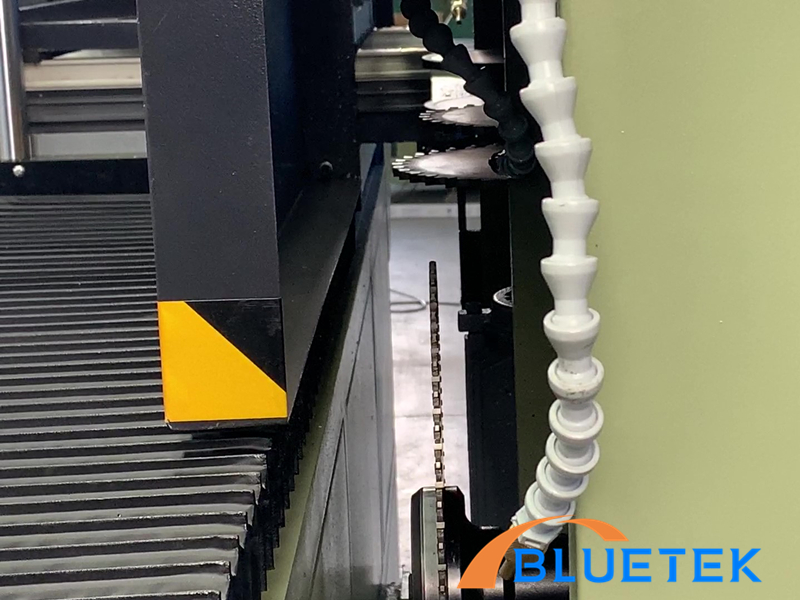

2. The combination of 5 pieces of saw blades : 4 pieces of saw blades in the horizontal direction and 1 piece of saw blade in the vertical direction. the end face tenon can be milled at one time, and the milling efficiency is high.

3. Super powerful function, can mill multiple middle mullion in one clamping, high work efficiency.

4. Through the up and down, front and back adjustment of saw blades, different structures such as stepped surface, rectangular groove and tenon can be processed. No need to customize tools, shorten the production cycle and reduce costs.

5. Saw blades diameter is large, milling range is large, cutting speed is high, and the quality of the machined surface is good.

6. This end milling machine aluminium adopts frequency conversion speed regulation to make milling more stable and efficient.

7. Aluminium window end milling machine frame adopts super rigid design, durable and not deformed. The saw blade adopts high-quality carbide saw blade, which has high cutting smoothness and low wear. The low-voltage electrical appliances are Schneider, the pneumatic components are Airtac, and the cylinders are joint venture brands. reliable quality.

Technical Parameters

| Product Name |

5 Blades Aluminium Window End Milling Machine |

| Product Model |

DX06A-250 |

| Power Supply | Customized |

| Input Power | 11 KW |

|

Air Pressure |

0.6 ~0.8 MPa |

| Air Consumption | 130L /min |

| Rotary Speed of Motor | 2800 r/min |

| Diameter of Blades | 250mm *4 ; 355mm*1 |

| Worktable Feed Stroke | 1500mm |

|

Tenoning Depth |

0~45 mm |

|

Tenoning Height |

30~130 mm |

| Overall Dimension | 2700*1550*1710mm |

| Weight | 1000 KG |

Detail Pictures

English

English Spanish

Spanish JINAN BLUETEK INTELLIGENT CO.,LTD.

JINAN BLUETEK INTELLIGENT CO.,LTD.