• The CNC glass cutting machine can move 360 degrees to realize automatic glass loading, glass transmission, automatic edge patrol positioning, optimization, glass cutting, glass breaking and other functions. (Optional functions: labeling, film removal, vacuuming)

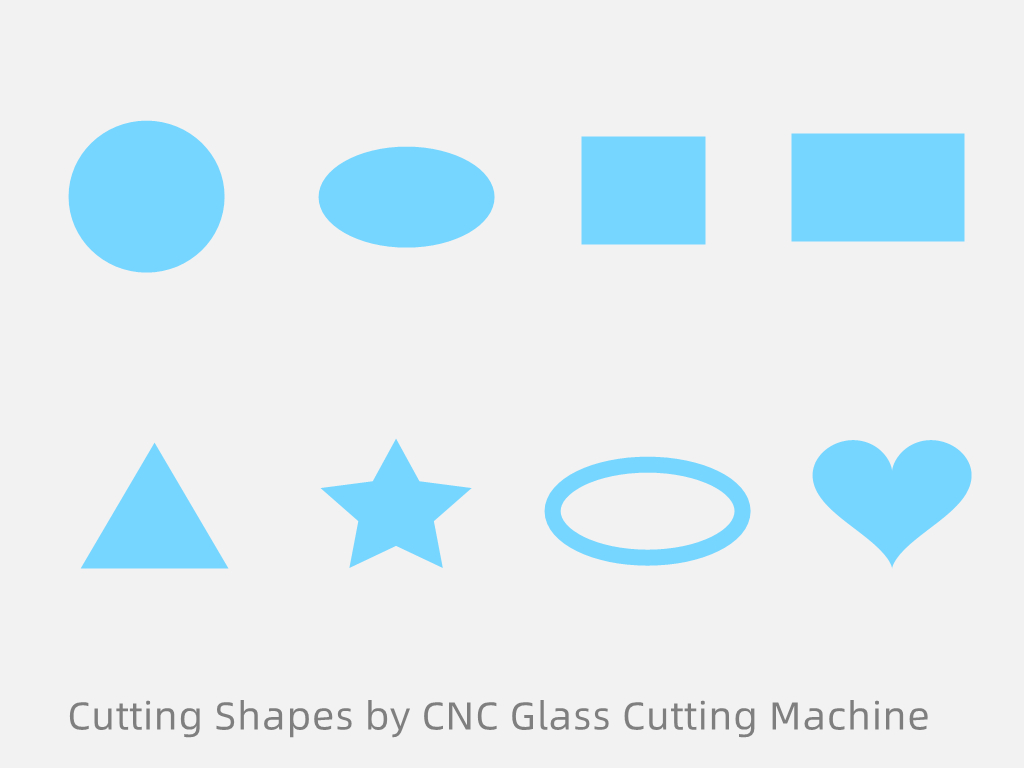

• It can cut straight and special-shaped glass, suitable for deep processing of architectural glass, decorative glass, home appliance glass, handicraft glass and other industries.

• Adopt bus absolute value servo motor, imported guide rail, rack and well-known pneumatic components to ensure the high precision and stability of the machine and long service life.

• Professional optimization software: Compatible with the Italian OPTIMA G code, realizing the versatility of different formats of files; the optimization rate of glass is the highest in China, improving the cutting rate and reducing glass waste and cost.

• Automatic glass edge finding and positioning: Accurately measure the actual position and deflection angle of the glass, realize automatic adjustment of the cutting path of the cutter head, and improve efficiency.

• Intelligent special-shaped scanning: The detector can intelligently scan special-shaped objects and automatically generate graphics by feedback to realize profiling and cutting.

• Automatic glass transfer: The cutting table of CNC glass cutting machine is equipped with a conveyor belt, which does not require manual transfer. The glass can be transferred to the air-floating breaking table through the conveyor belt, and the breaking operation is carried out on the breaking table.

• The automatic oil filling and automatic pressure adjustment functions of the cutting head can effectively ensure the cutting stability and cutting effect.

• Easy for operation. There are no special requirements for operators, and the operation is simple and easy to manage. The machine only needs two workers, one for operation and one for breaking pieces, and the production efficiency is high.

Technical Parameters

glass loading, glass transmission, automatic edge patrol positioning,

optimization, glass cutting, glass breaking

Air pressure

0.6 - 0.8Mpa

3~19mm

X axis beam speed

0 ~ 200m / min

Cutting accuracy

Glass loading depth

0-700mm

Table height

800mm +/- 30mm

Machine Size

5700X5000X1700mm

2800KG

Model

LKBQ-CNC-3826

Product Name

CNC Glass Cutting Machine

Function

Total Power

13 KW

Max. Cutting Size

3660 * 2440 mm

Cutting Thickness

Y axis beam speed

0~ 200m / min

+/- 0.2mm

Weight

Quantity of Loading Arms

3

Quantity of Sucker

12

Detail Pictures

What are the advantages of CNC glass cutting machine compared with manual glass cutting machine ?

CNC glass cutting machine offer several advantages over manual glass cutting machine. Here are some key advantages:

Precision and Accuracy: CNC glass cutting machines are highly precise and accurate due to their automated control system. They follow pre-programmed instructions, ensuring consistent cuts with minimal errors. This level of precision is difficult to achieve consistently with manual cutting methods.

Complex and Intricate Designs: CNC machines excel at cutting complex and intricate designs. By using computer-aided design (CAD) software, you can create intricate patterns or shapes that can be accurately replicated by the CNC glass cutting machine. Manual cutting methods are limited in their ability to achieve such intricate designs.

Time and Efficiency: CNC glass cutting machine is faster and more efficient than manual methods. They can rapidly execute cutting operations, resulting in shorter production cycles and increased productivity. Additionally, multiple cutting tasks can be performed simultaneously or sequentially, further saving time.

Reduced Waste: CNC machines optimize material usage, reducing waste compared to manual cutting. The precise cutting paths and nesting capabilities of CNC glass cutting machines minimize the amount of scrap generated. This helps optimize material costs and improve overall efficiency.

Consistency and Replication: CNC glass cutting machine can consistently replicate cuts, ensuring uniformity across multiple glass pieces. This is particularly valuable in applications where identical or matching glass components are required, such as in the production of windows or glass panels for architectural purposes.

Safety: CNC machines provide a higher level of safety compared to manual glass cutting machine. Operators are not required to directly handle sharp cutting tools, reducing the risk of injuries. The automation and enclosed design of CNC machines contribute to a safer working environment.

Flexibility and Adaptability: CNC glass cutting machines offer flexibility and adaptability to accommodate various glass types, sizes, and thicknesses. They can be easily reprogrammed to switch between different cutting patterns or designs, making them suitable for diverse manufacturing needs.

Reduced Skill Requirement: While manual glass cutting requires skilled operators with extensive experience, CNC machines are relatively easier to operate. Although some initial training is necessary to operate CNC glass cutting machines effectively, the skill requirement is generally lower, enabling less experienced operators to achieve high-quality results.

It's worth noting that CNC glass cutting machine may have higher upfront costs compared to manual machines. However, the long-term benefits, such as increased productivity, reduced waste, and improved quality, often outweigh the initial investment.

English

English Spanish

Spanish JINAN BLUETEK INTELLIGENT CO.,LTD.

JINAN BLUETEK INTELLIGENT CO.,LTD.