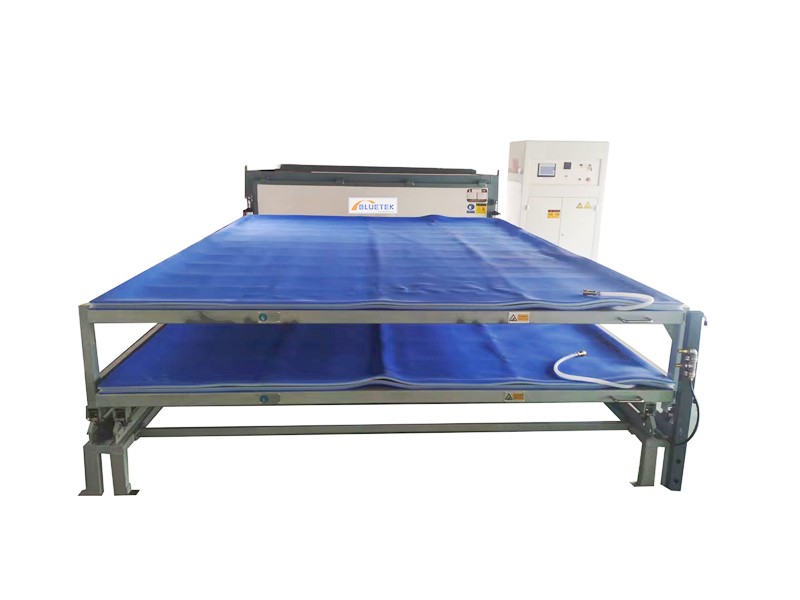

Working Principle of EVA Laminating Glass Furnace

The vacuum bag heats the glass and the EVA film together under the condition of heating and vacuuming, that is, the safety laminated glass is formed.

Characteristics of Laminating Glass Furnace:

Doesn't need autoclave, low production cost; simple operation, low energy consumption and high efficiency.

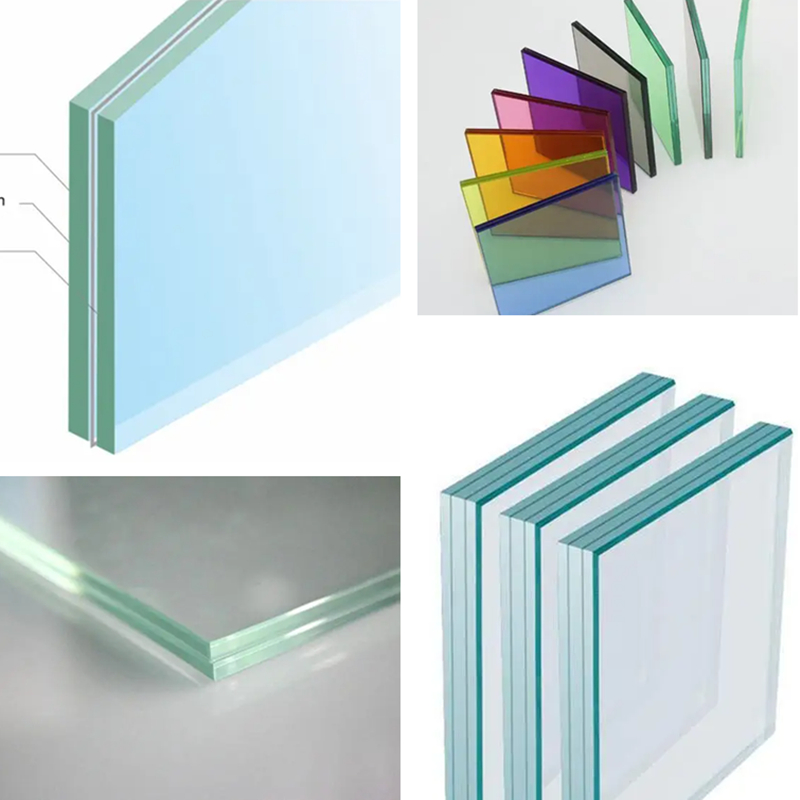

Laminated glass has many advantages such as high strength, waterproof, safety and explosion-proof.

Applications of Laminating Glass Furnace:

laminated glass, wired glass, dry laminated glass, photo art glass, photo studio crystal photo bulletproof glass, landscape wall sliding door glass, closet partition, etc.

Operating Procedures

1. Putting the glass, putting the film, putting the drawing, putting the film, putting the glass.

2. Cutting the excess waste on the four sides.

3. Repeat steps 1 and 2, the glass thickness is 5 cm and 10 pieces as the standard

4. Putting the paved glass into the stove, large pieces, long pieces of glass are placed below, small pieces, short pieces are placed

On top, and then place the gasket to protect the four corners of the glass so as not to puncture the vacuum bag.

5. Cover the position of the air extraction hole with a blanket, put a small wooden strip on the edge of the glass to the air extraction opening, and the air extraction effect is better, and then close the vacuum bag.

6. Setting the time and temperature.

7. Turn on the power of the vacuum pump, the air pressure is -0.1, and check whether the vacuum bag is tightened.

8. Close the machine cover.

9. Turn on the heating power, turn on the circulating fan, and keep the vacuum

10. When the temperature drops below 50 degrees in summer, and below 40 degrees in winter, the temperature standard is based on the temperature of the tempered glass inside the explosion-proof machine. Only then can the vacuum bag be opened, the power of the vacuum pump be turned off, and the fan can be turned off.

Technical Parameters

Product Name

EVA Laminating Glass Furnace

Model

JJL-2-2

Power Voltage

220V , 380V, 415V , Customized

Input Power

35 KW

Vacuum Bed Quantity

2 Layers

Max. Glass Size

3660*2440mm

Overall Dimension

8500*3000*1620mm

Gross Weight

3400 KG

Fans' Quantity

6 Sets

Customization of Glass Processing Size

Yes

Products of Laminating Glass Furnace

Packing and Shipping For Glass Laminating Furnace

The two layers glass laminating furnace needs to be loaded in a 20-foot container. The outer packaging of the furnace is fumigation-free plywood to avoid scratches and damages to the machine during shipping.

English

English Spanish

Spanish JINAN BLUETEK INTELLIGENT CO.,LTD.

JINAN BLUETEK INTELLIGENT CO.,LTD.