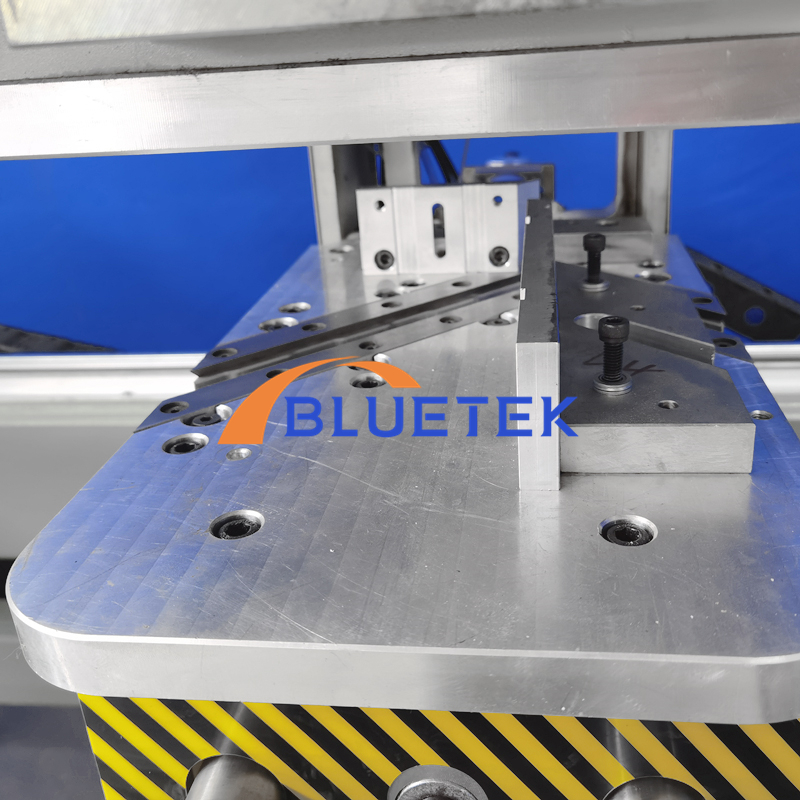

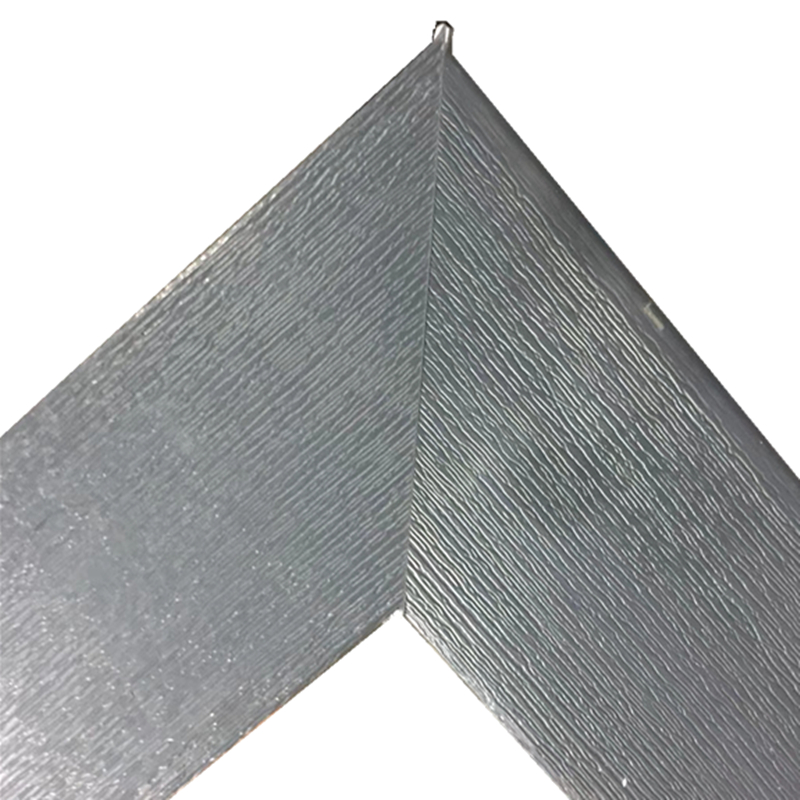

2. The upper and lower knife cut off the welding slag during the welding process to realize double sides seamless. Not only the welding effect is very good, but also the corner strength of the window corner is high.

3. The cutting knife is made of alloy material and processed by high-frequency quenching to realize the standardization of the cutting knife and support the replacement of the cutting knife.

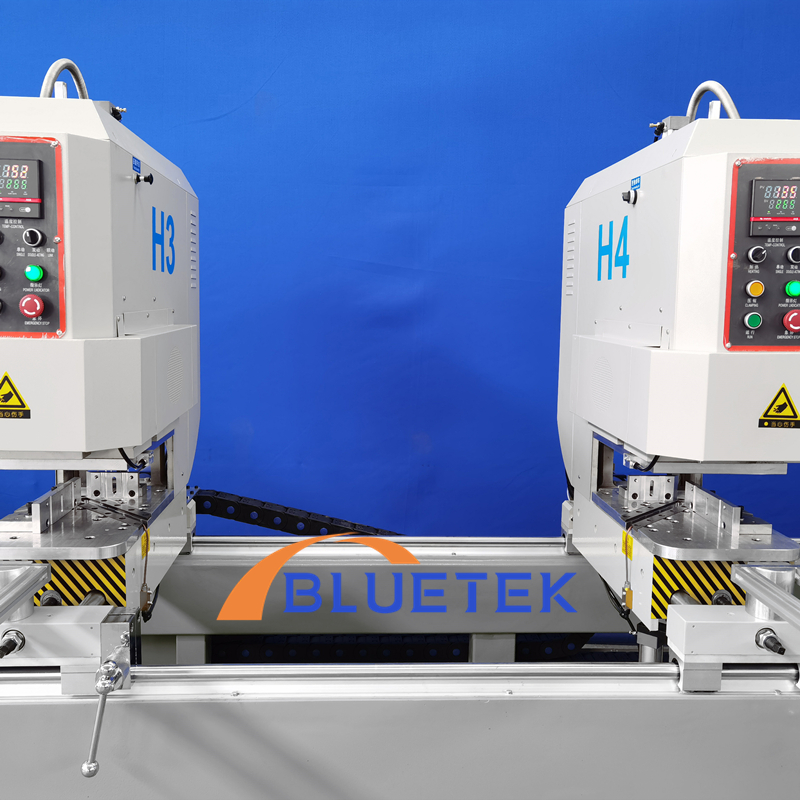

4. The welding process is controlled by Japan Omron Programmable Logic Controller (PLC), which is stable and reliable, and has a high degree of automation.

5. UPVC Window Welding Machine heads can work individually or jointly to realize welding such as ┏, ┏┓, and ┏┳.

6. The compression system adopts the main compression clamp and the auxiliary compression clamp to prevent the main compression clamp from deforming due to excessive pressure.

7. The low-voltage electrical appliances adopt French Schneider, and the power switch adopts Japanese Omron, with stable and reliable quality.

8. The heating time and cooling time are both 25 seconds. In theory, it takes two minutes to weld a rectangular window frame. The annual output of a single shift is about 8000 ~ 10000 square meters.

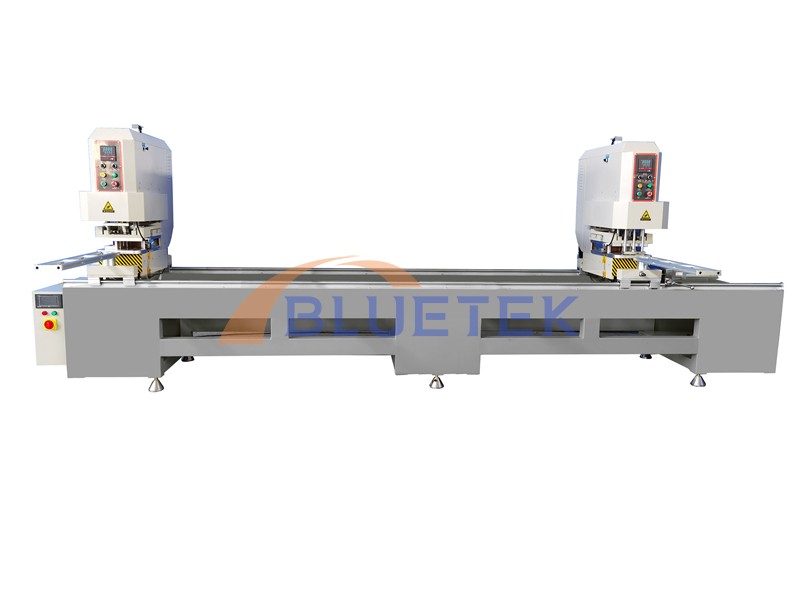

Technical Parameters

Model

WFH-2

Product Name

Double Heads UPVC Window Seamless Welding Machine

Power Supply

220V 50Hz

Input Power

2.5 KW

Air Pressure

0.5 ~0.8 MPa

Welding Profile Height

20~120 mm

Welding Profile Width

120 mm

Welding Profile Length

400~3500 mm

Overall Dimension

4600*1200*2050 mm

Weight

1500 KGS

Detail Pictures

FAQ:

How To Install and Operate Double Heads UPVC Window Seamless Welding Machine ?

Instruction Manual Of PVC Window Seamless Welding Machine

English

English Spanish

Spanish JINAN BLUETEK INTELLIGENT CO.,LTD.

JINAN BLUETEK INTELLIGENT CO.,LTD.