How To Make UPVC Window and Door ?

Many customers and friends don't know much about the UPVC window and door industry, often ask how to make UPVC window door, which PVC window door manufacturing machine is needed, and how much investment is required. As the manufacturer of pvc window door manufacturing machine for 16 years, we answer these questions in this article.

There is a famous saying in China: Sharp tools make good work. how to make UPVC window door ? If we want to produce good UPVC window door, we need choose the most suitable PVC window door manufacturing machine.

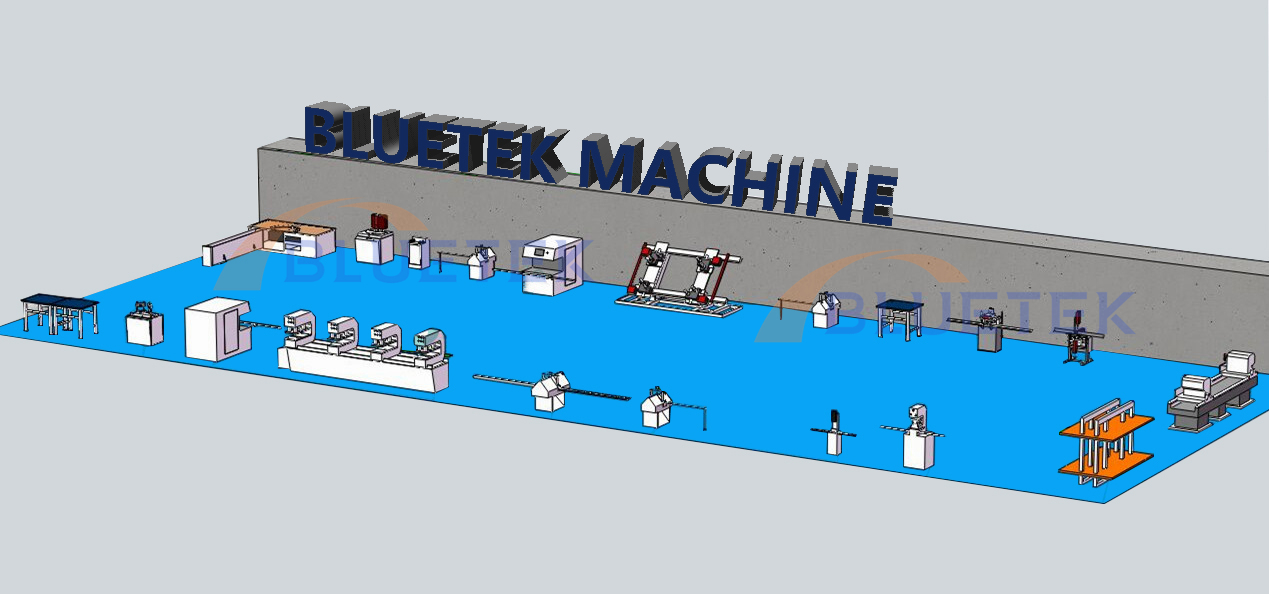

The PVC door and window manufacturing is a complete production line, from sawing profiles, milling holes, to cleaning corner seams, installing hardware and glass, each step requires a different machine to complete.

1. UPVC window double heads cutting machine (sawing PVC profiles for different lengths, cutting 45 and 90 degree angle)

2. Water slot milling machine 2/3 heads (milling drain holes and air pressure balance holes)

3. Copy router machine, also known as Lock hole processing machine (drilling handle holes and other hardware mounting holes)

4. V-cut saw (cut V-shaped notch for window frame, for middle mullion welding and joining)

5. Screw drilling and fastening machine or hand-held electric drill (after placing the reinforcement steel in the chamber of PVC profile, fix it with screws)

6. PVC window door welding machine (welding window corners and mullion, according to capital budget and output, you can choose single-head welding machine, double-head welding machine, three-head welding machine, four-head welding machine; each type of welding machine is divided into ordinary welding machine and seamless welding machine, ordinary welding machine processing ordinary white PVC profiles, seamless welding machine processing color film coated profiles and color co-extrusion profiles. The most important pvc window door manufacturing machine is the welding machine, which determines the output and quality. Choosing the right welding machine is half the battle.)

7. PVC door and window corner cleaning machine (manual, semi-automatic and CNC full-automatic corner seam cleaning machine, use milling cutter and saw blade to clean up the welding tumor of the window corner, so that the window corner is beautiful and beautiful)

8. Glass bead cutting saw (special cutting saw for glass bead)

9. UPVC window arc bending machine (a necessary machine for processing arc-shaped doors and windows, you can also add a single-head arbitrary angle welding machine that can weld 30~180 degrees, which is more efficient)

These are commonly PVC window door manufacturing machine used for processing conventional windows and doors, with prices ranging from a few thousand dollars to tens of thousands of dollars. Customers need to choose the most suitable pvc window door manufacturing machine according to the capital budget and output.

English

English Spanish

Spanish JINAN BLUETEK INTELLIGENT CO.,LTD.

JINAN BLUETEK INTELLIGENT CO.,LTD.