Double-head PVC window seamless welding machine is currently the best-selling welding machine, and the double-sided seamless welding makes the colored doors and windows more beautiful. But, due to the language and low after-sales service capabilities of suppliers, many customers complain that they do not know how to install seamless welding machine by themselves.

In order to allow customers to complete the installation and operation themselves, BLUETEK has compiled this concise and efficient user manual, which can greatly improve the installation efficiency of PVC window seamless welding machine.

1. Electricity Connection ( Single Phase )

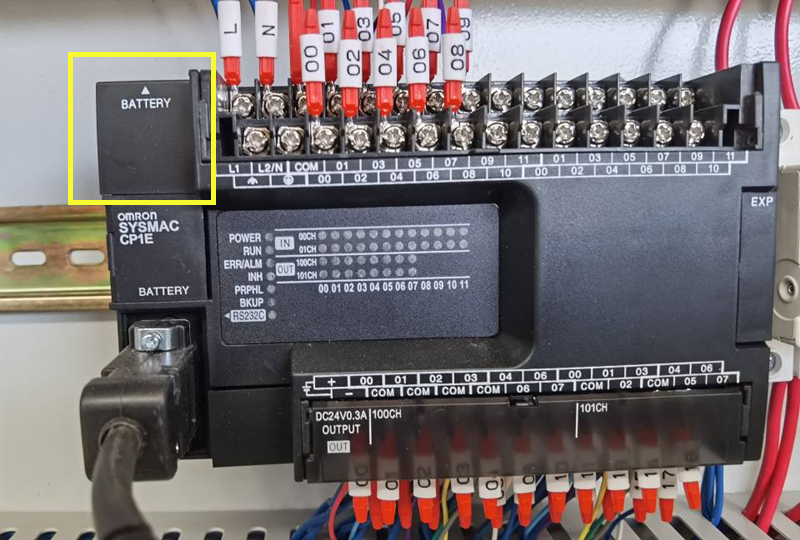

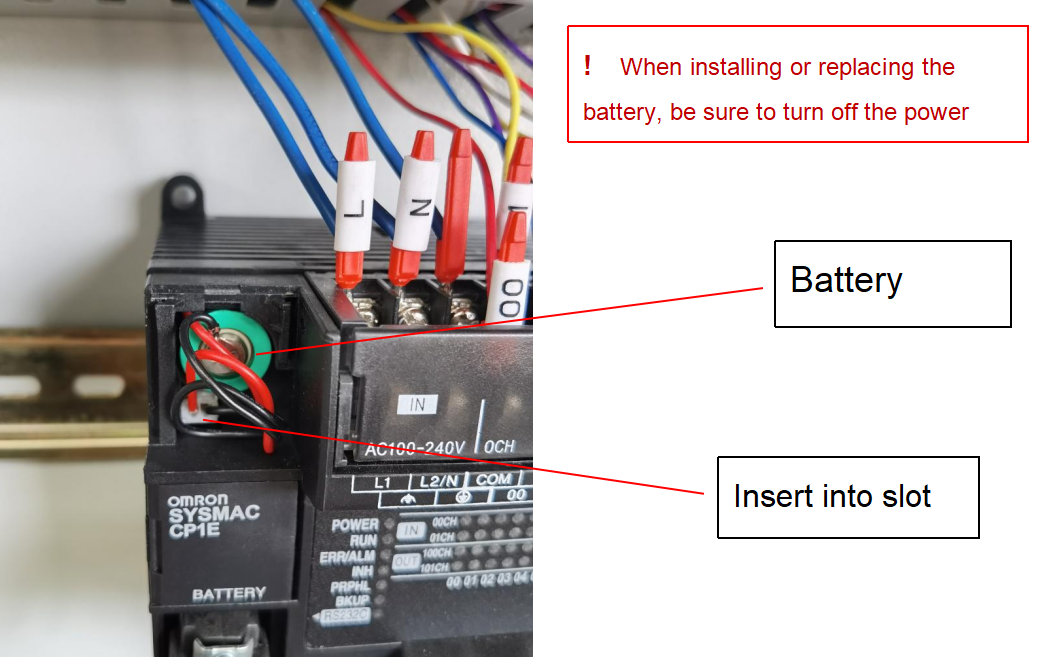

If the PVC window seamless welding machine adopts Omron PLC, firstly, we need install the cylindrical battery in the upper left corner of the PLC ( refer to the picture ) and insert the battery connector into the slot.

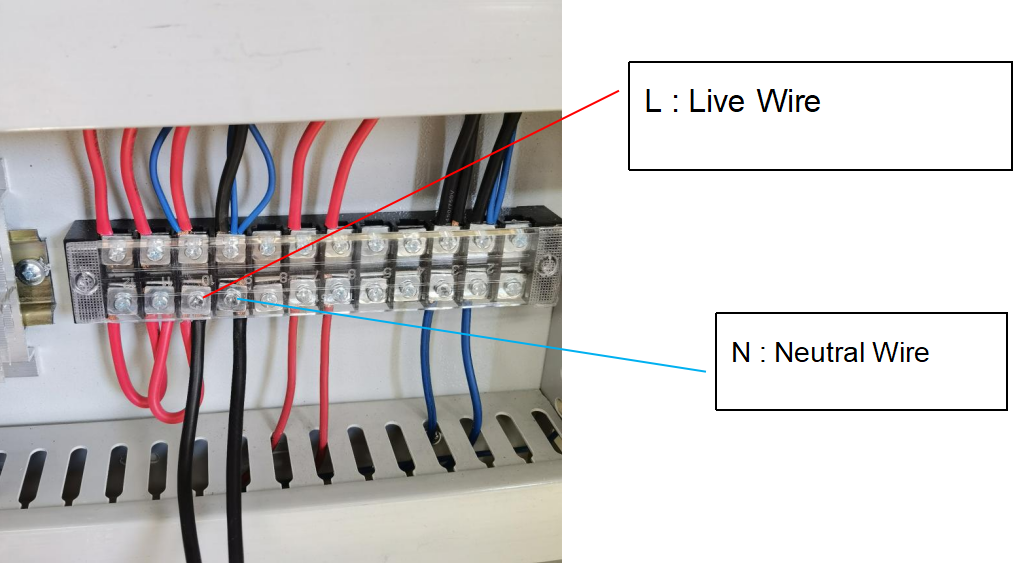

One Live Wire, one Neutral Wire, connecting to the machine according to bellow picture.

After completing the power connection, turn on the power switch on the electric box,

The indicator (green light) lights up

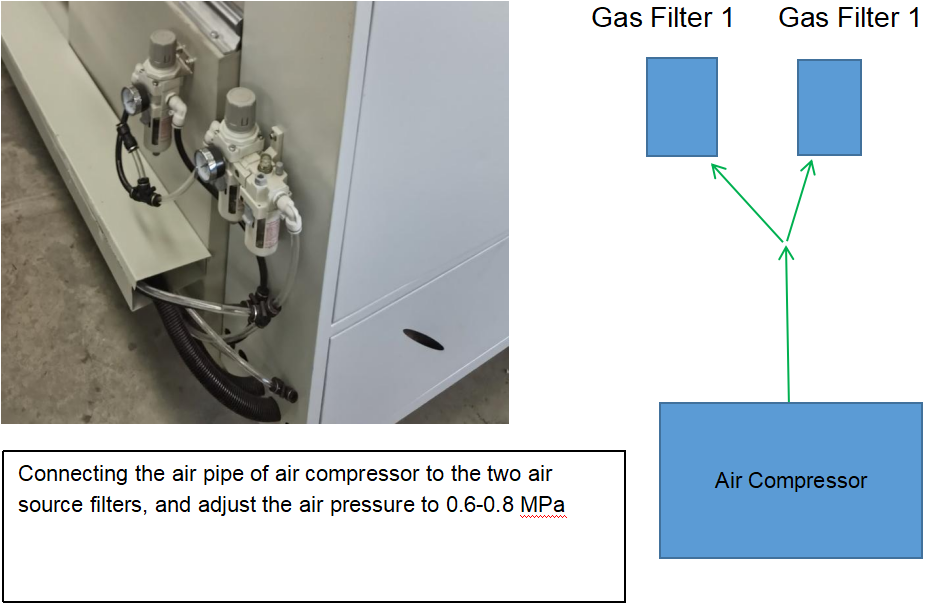

2. Air Connection

Double Head PVC window seamless welding machine has 2 pieces of air filters

Pull up the cap of the air filter, turn it clockwise or counterclockwise, and adjust the position of the pointer. Press the cap when finished.

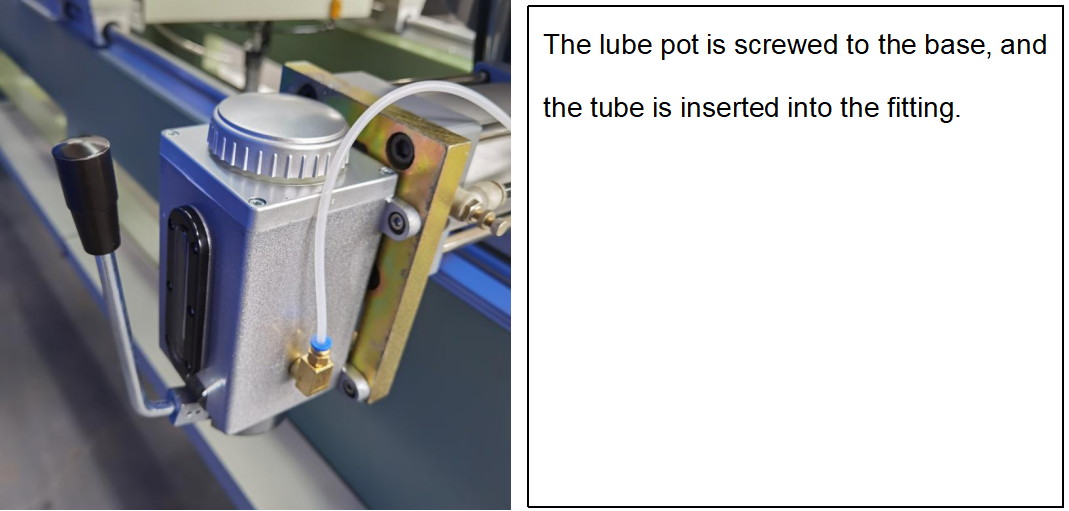

3. Lubricating Oil Pot Installation

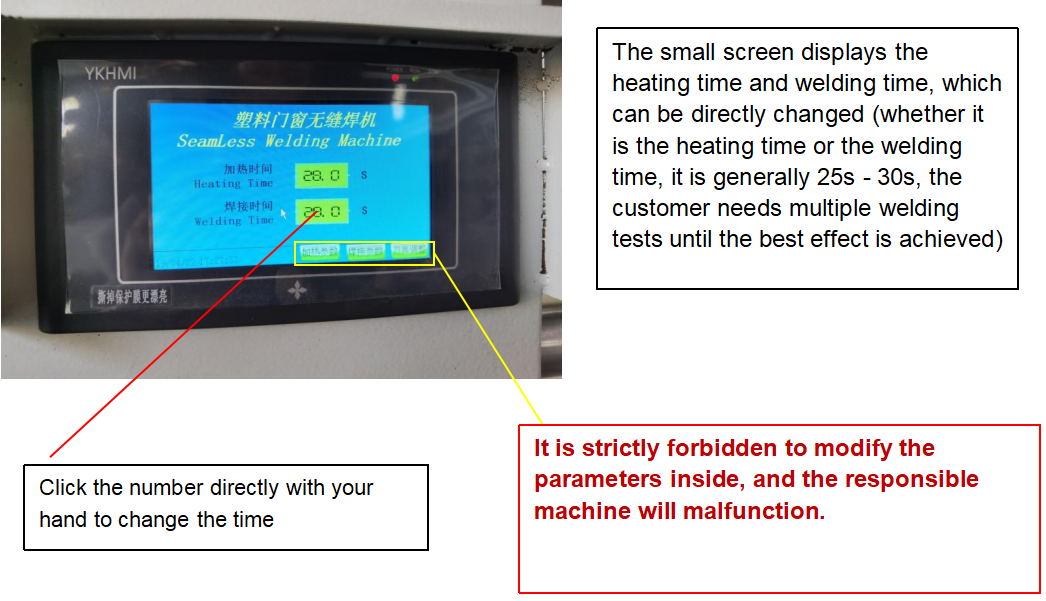

4. Operation

4.1 Turnning " HEATING " to the right  , the heating is turned on, the welding plate starts to heat, and the general setting temperature is 250℃ ~ 260℃

, the heating is turned on, the welding plate starts to heat, and the general setting temperature is 250℃ ~ 260℃

4.2 Choosing " DOUBLE ACTING " , so that two heads can weld and cool together; If it is Three Head / Four Head Welding Machine , please choose " LINK "

, so that two heads can weld and cool together; If it is Three Head / Four Head Welding Machine , please choose " LINK "

4.3 When the actual temperature reaches the preset temperature, we will start welding.

Press " RUN "  , bottom location plate will rise up.

, bottom location plate will rise up.

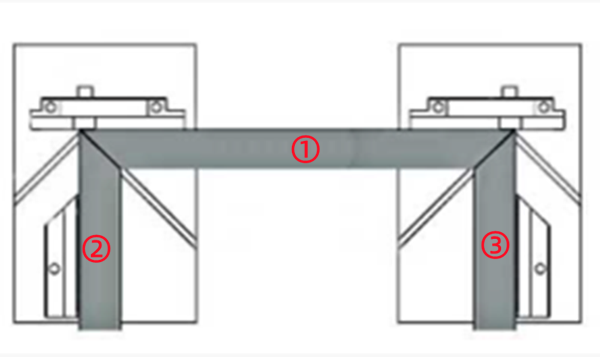

4.4 Putting the first piece of PVC profile ( No.1), and move the right head, make sure that the section of the PVC profile and the positioning plate will be touched closely to each other, then lock right head.

4.5 Putting the second piece of PVC profile ( No. 2 ), press " CLAMP " , then front clamper and back clamper will fall together, pressing the No. 1 and No. 2 PVC profiles ;

, then front clamper and back clamper will fall together, pressing the No. 1 and No. 2 PVC profiles ;

Putting No.3 PVC profile for right head, press " CLAMP " , then front clamper and back clamper will fall together, pressing the No. 1 and No. 3 PVC profiles.

, then front clamper and back clamper will fall together, pressing the No. 1 and No. 3 PVC profiles.

4.6 Press " RUN "  ( each head is both available ) , then two heads of PVC window seamless welding machine will complate automatically of welding and cooling.

( each head is both available ) , then two heads of PVC window seamless welding machine will complate automatically of welding and cooling.

Supplementary Instructions

Press  " Auxiliary Clamp " will fall.

" Auxiliary Clamp " will fall.

Press  " Change The Welding Cloth " , heating plate will fall, it is easier to replace welding paper.

" Change The Welding Cloth " , heating plate will fall, it is easier to replace welding paper.

!!! When replacing the welding cloth, make sure that the heating plate has been cooled for a long time to bring the temperature down to room temperature, to avoid being scalded !

English

English Spanish

Spanish JINAN BLUETEK INTELLIGENT CO.,LTD.

JINAN BLUETEK INTELLIGENT CO.,LTD.